CHANGING THE LUBRICATING OIL of SICOMA Concrete Mixer

Since the reduction gears have been designed not to consume oil, change the oil EVERY 4000

HOURS or at least EVERY 2 YEARS.

When changing or refilling oil in the reductors, oil-pressure system and bearings, use the type of oil shown in the table below, while for the refilling of the seals lubricating system tank

CHANGING THE HYDRAULIC OIL IN THE OIL-PRESSURE SYSTEM

| TYPE QUANTITY | ISO-UNI 150

Litres 16 |

ISO-UNI HM 46

Litres 10 |

ISO-UNI G 150

Litres 0.5 |

|

MAKE |

REDUCTION GEAR |

HYDRAULIC SYSTEM |

BEARINGS |

| BP | GR150XP | HLD46 | GR150XP |

| TEXACO | MEROPA LUBR.L150 | RAND OIL HD 46 | MEROPA LUBR.L150 |

| AGIP | BLASIA 150 | OSO 46 | BLASIA 150 |

| ESSO | SPARTAN EP 150 | NUTO H 46 | SPARTAN EP 150 |

| MOBIL | MOBILGEAR 629 | DTE 25 | MOBILGEAR 629 |

| SHELL | OMALA OIL 150 | TELLUS S 46 | OMALA OIL 150 |

| TOTAL | CARTER EP 150 | AZOLLA 46 | CARTER EP 150 |

| ROL | EP 150 | LI 46 | EP 150 |

SEALS LUBRICATION

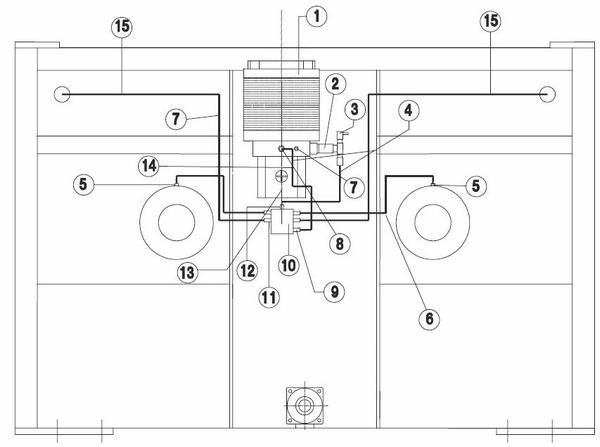

Grese centralised lubricating system mounted on twin shaft mixers MAO series consists of:

– Pump with a dispenser grease capacity 4 kg (4,3 lt.), weight capacity 2,5 cc/min. – 150 cc/h –

pressure max. 25 MPA (250 bar) with recycling system which reduces the capacity to 1,65 cc/min.

100 cc/h.

– Two phases ON/OFF time-switch (to insert in the junction box connecting this to the rope that

feed the pump)

– Direct current power 24 V. / 120 W (for rotation way see needle signed on the pump body)

– Control electric devise minimum level

– Control pressure gauge

– Modular progressive dispenser

WORKING of GRESE PUMP

The grease pump power must start pumping when the mixer start working; considering that the necessary grease quantity for the four seals lubrication during one work shift of 8 hours is about

200cc, the time-switch has to be regulated as follows:

Pump time working: 120″ – break time 360″: in this way, it is obtained a continuous lubrication of the four seals on the inner side, in contact with the concrete, while on the external side (GNL –

Gasket) and on the bearings the lubrication is made by oil in air tight chamber.

In any case, if the dispenser should run out of oil it is soon signaled by the minimum level. Also the progressive dispencer is provided with a signalling that, at each cycle, signal that the greasing cycle of the four points to be lubricated has been carried out. The pump pushes the pressured grease to the progressive dispenser through the connecting pipe, then the progressive dispenser pushes it to the four seales, by their respective rubber tubes. The dispenser works in a progressive way, that is each point is lubricated in sequence after finishing the lubrication of the previous point, which is through the action of a series of pistons placed in its area, piloted, one to the other, in an interdependent sequence, caused by the lubricating flow. The last point to be lubricated is provided with a signalling activated by the bar of the little piston which moves. At each cycle, the emitted signal confirms that the four points lubrication has been carried out. If for any reason the pipe line is obstructed and the grease does not gets through, the signalling placed on the last little piston is not excited, therefore, the lubrication is not signaled.This signalling should be insert in the control panel. For the electric connection, follow what is said above and consult the pump instruction manual. The filling or the topping up must be done with the specially provided connection, through a pneumatic or manual barrel pump. It is not recommended, also because it is problematic, the filling up by removing the reservoir cover, since introducing air and foreign matter could compromise the pump working. The pump is fitted with an inner blade which pushes the grease in order to facilitate the suction and pumping.

The grease to be used must be of an adhesive and water-proof type, with a very good resistance to washing away. The consistency recommended must be NLG1

GREASING

Greasing of the unloading door bearings , of the hydraulic cylinder pivots and of the motors supports’ pivots is made trough standard greasers.

Greasing must be effected every 250 working hours, or at least once in a month.Use TEXACO MULTIFAK MP 2 grease, or equivalent grease, with UNI XM 2 gradation

| MARK | AGIP | BP | ESSO | MOBIL | ROL | SHELL | TEXACO | TOTAL |

| TYPE | GR MU EP2 |

LTX2-EP |

BEACON 2 |

MOBIL PLEX 47 | LITEX EP2 | SUPER

GREASE R2 |

MULTIFAK MP2 | MULTIS EP 2 |