Introduction of mixer truck PMP reducer and related fault solutions

In industrial applications, the reducer has the function of decelerating and increasing torque. Therefore, it is widely used in speed and torque conversion equipment. PMP reducers are widely used in the concrete mixer truck market with high reliability and high cost performance.

PMP reducer introduction

PMP’s mixer truck reducer products cover 6-16 cubic meters of mixer trucks, and it is the only manufacturer in the world that can mass produce 16 cubic meters of mixer truck reducers. The PMP reducer has a large installation angle, a large output torque, and can withstand load conditions under various working conditions. It has a high safety factor, a large torque margin, and a stable quality. PMP reducers have entered the Chinese market since 2001, and there are currently more than 20,000 reducers serving the Chinese market. In the mixer truck market, mixer trucks with PMP reducers have achieved better sales.

Since PMP entered the Chinese market, it has been favored by a large number of users. It has been widely used in various domestic mixer truck manufacturers and has become the first choice for users to buy vehicles. Long-term supporting domestic manufacturers include: Anhui Xingma, Foton Lovol, Sany Heavy Industry, Qingdao Heavy Truck, CIMC Lingyu, CIMC Tonghua, Hangzhou Special Automobile, Dongfeng Special Automobile, Hubei Construction Machinery, Tangshan Hongda, JAC Automobile, Wuhu Ruijiang, Shandong CIMC, Shandong Lufeng, etc.

Comparison of technical parameters of PMP reducer

| Model | Max. output torque N.M | Ratio | Max input speed rpm | Mixer capacity m³ | Weight

Kg |

Lubricating oil capacity L |

| PMB 6SP | 60000 | 1:99.9 | 2500 | 6-8 | 270 | 12 |

| PMB 7ASP | 60000 | 1:120.3 | 2500 | 9-10 | 290 | 13 |

| PMB 7BSP | 70000 | 1:129.1 | 2500 | 10-12 | 330 | 15 |

| PMB 8SP | 80000 | 1: | 2500 | 14-16 | 367 | 17 |

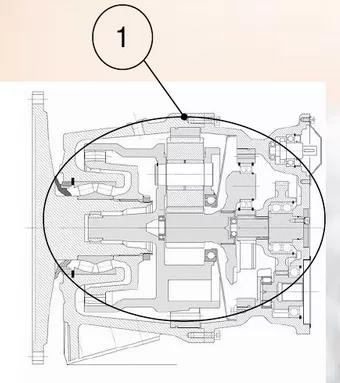

Advantages of PMP reducer gearbox

The entire reducer is a closed oil tank, so it can be lubricated by gear oil without the use of butter, and the maintenance is simple and convenient.

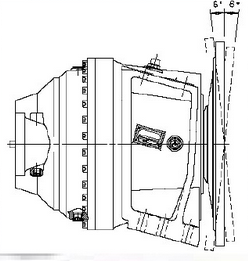

The main bearing is an exclusive design, so that the drum flange has a +/- 6 degree swing angle. Therefore, it can absorb installation errors, better adapt to different working conditions, and extend the life of the reducer.

Two locking devices are used in the shaft and bearing oil area. The gap between the bearing and the output flange can be eliminated, so that the two are always closely matched to eliminate noise and ensure quality.

All cast steel of the reducer has passed NDT inspection (ultrasonic detection, three cuts). Ensure that there are no defects such as blisters, cracks, etc. Separate the ring gear and the shell into a single body for processing, using carburized steel as the raw material, and a special heat treatment method. It ensures high surface hardness of the gear ring, good internal elasticity and flexibility, and strong strain force, improves transmission accuracy, reduces noise, ensures clean oil quality, and facilitates maintenance.

A butterfly spring is installed on the secondary reduction bearing, which compensates for bearing wear and eliminates the gap, so that the startability and loadability of the reducer are better.

Common faults and maintenance methods of PMP reducer

1. Oil seal leakage: oil seal leakage is mostly caused by scratches on the main oil seal of the reducer or scratches on the output shaft of the reducer and entanglement of foreign objects due to improper use.

Troubleshooting: a. Replace the reducer; b. Replace the oil seal, and clean the foreign matter in the oil seal in time during use.

2. Oil leakage at the connection between the end cover and the shell: This type of oil leakage is mostly caused by the loosening of the connecting bolts of the reducer.

Troubleshooting: a. Tighten the connecting bolts of the end cover and the shell; b. Replace the reducer; c. Replace the O-ring between the end cover of the reducer and the shell. In order to effectively avoid this kind of situation, the reducer should be prevented from being severely impacted, and the bolt torque should be checked regularly.

3. Oil-filling and draining plug, oil level observation window, oil leakage from vent holes: This type of oil leakage is mostly caused by insufficient re-tightening or deformation of gaskets or excessive filling of gear oil after filling and draining.

Troubleshooting: a. Re-tighten the oil plug or oil level observation window and vent plug; b. Replace the gasket. For such situations, check and tighten them regularly to observe whether there has been a collision. Such vulnerable parts are easily damaged by external forces.

4. Oil leakage at the connection of the motor and the reducer: The oil leakage at the interface of the motor and the reducer is mainly because the installation of the O-ring during installation does not meet the requirements of complete sealing.

Troubleshooting: a. Replace the О-shaped ring at the junction of the motor and the reducer; b. Check whether the mounting surface of the motor and the reducer is scratched. During use, check whether the mounting bolts of the motor and reducer are loose.

Fault Class B: Abnormal sound

1. Abnormal noise of reducer

If you find abnormal noise in the reducer during use, you can do the following inspections:

(1) Check whether there is gear oil in the reducer.

(2) Check whether the oil level is normal at the oil level observation window.

(3) Release a small amount of oil to see if there is any blackening and deterioration and check the maintenance time.

(4) Check whether the reducer has been impacted by external forces.

If a large amount of iron cut is found in the oil drain, it can be determined that the inside of the reducer has been damaged. Solution: Stop using the reducer immediately and replace it with a new one. To avoid such situations, pay attention to the regular oil change and maintenance of the reducer.

2. The abnormal noise of the vehicle under heavy load

As shown in the figure, the angle of the flange of the reducer changes under heavy load and the deviation of the upper and lower angles is too large, which has exceeded the maximum inclination required by the reducer, which will easily cause abnormal noise of the reducer.

3. Abnormal noise or jitter of the reducer “buzzing”

Such failures are mostly caused by oil pumps and motors, and the aggregates in the tank can also cause abnormal noise and jitter of the reducer. When encountering such problems, you can check the oil condition in the reducer first, and all the gear oil must be discharged for inspection. If no abnormality of the gear oil is found, it can be confirmed that the reducer is operating normally. If there is such a condition, please check the oil pump, motor and tank.

Failure C level: stuck

If the tank suddenly stops rotating, you can first check whether the oil pump motor is working properly. The problem can be simply judged from the hydraulic oil. If there is iron chipping or deterioration in the hydraulic oil, it can cause the internal wear and tear of the oil pump motor to stop working. You can find a vehicle with a normal oil pump motor and connect the motor to the failed vehicle for experimentation.

If you check the normal operation of the oil pump motor, you can check that the reducer is also inspected for draining. If there is iron chipping in the oil, the reducer has been damaged and must be replaced. If the above situation occurs, there is still concrete in the tank, please clean it up immediately to avoid greater losses.