PLY1000 Batching Controller

PLY1000 batching controller is mainly applicable to the concrete mixing plant or station in the construction industry, and is used to control the automatic weighing, automatic batching and automatic mixing of multiple scales (6, including bone scales, cement scales, water scales, extra-liquid agent scales, fly ash scales, and standby scales) in the multi-bin batching system.

The PLY1000 batching controller is designed based on the control principle of various (productivity and structural form) concrete mixing plants and various concrete mixing plants: the rack-mounted case is adopted to improve the structural level of the whole machine. The printer can be connected according to user requirements.

The controller adopts advanced integrated circuit, highly reliable device and modular design, and has the characteristics of high weighing accuracy, simple operation, reasonable price and high reliability.

PLY1000 batching controller has RS-232 serial communication port, which can be connected with PC conveniently and reliably to realize stronger management function and screen display function, so that the control system can meet the needs of different users.

The instrument design is based on the following standards: GB/T7724-1999 Weighing Display Controller

Working conditions

Power supply voltage: AC 220V-15%~220V+10%, 50Hz ± 2%

Working ambient temperature: 0~+40 ℃

Relative humidity:<85% RH

In case of special use conditions (refer to Article 3.3 of GB3797-89;

Power consumption: < 100W

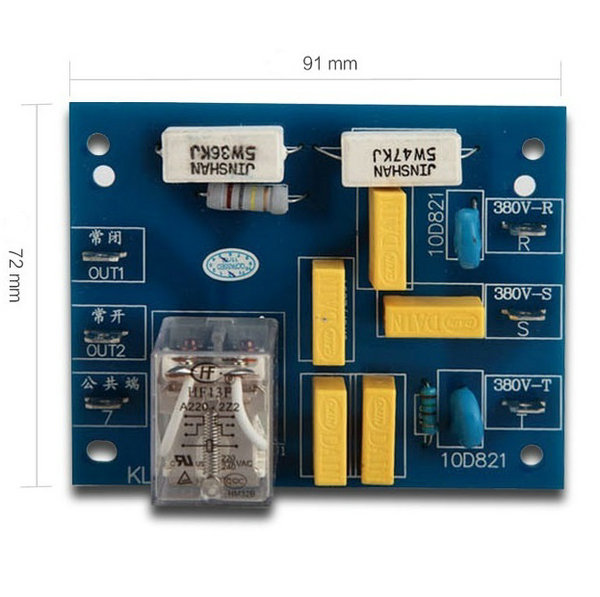

Switching Power Supply

3A, 24V power supply: convert AC220V into DC24V power supply provided by driving small relay, etc., with the maximum driving current of 3A. With wide voltage input and output overload protection function.

Formula

The controller can store 10 groups of formulas at the same time, which are respectively represented by formula numbers 0-9, for calling and modification at any time, without losing power. Each formula includes: aggregate, cement, fly ash, water, extra-liquid agent, etc.

Weighing display performance

Input signal: DC0~20mV

Accuracy class: Class 4

Cement display: n-1000 calibration graduation: c-1

Aggregate display: n=1000 Calibration graduation: c=1

Water display: n=1000 Calibration scale: c=0.1

External liquid agent display: n=1000 calibration graduation: c=0.01

Fly ash display: n-1000 calibration graduation: c-D1n.com

The measuring range of each scale=n * d, and the verification shall be subject to the actual measurement performance requirements of each supporting scale.