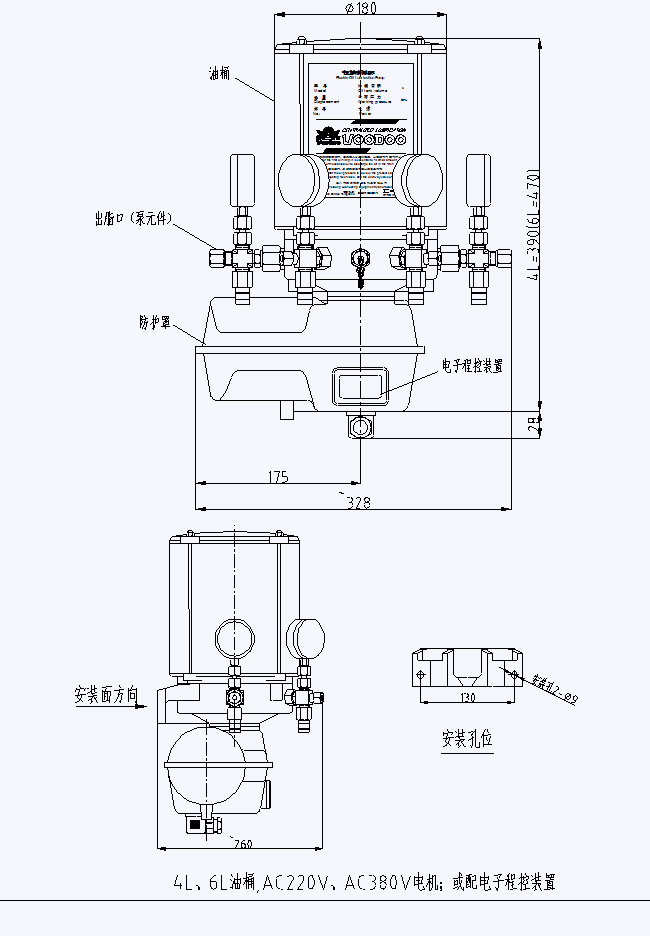

4WDB-M Electric lubrication pump

• 1~6 grease outlets.

• Optional pressure gauge and safety relief valve can be mounted at the grease outlet, which is convenient to observe the condition of lubrication points and the lubrication pump.

• With waterproof and dustproof function, the fully sealed lubrication pump can be applied to forging and pressing equipment, construction machinery, rubber and plastic equipment, vehicle chassis, etc. and is applicable to field operation.

• Optional built-in programme control.

• Each grease outlet can be directly connected with lubrication point and can also be connected independently with progressive distributor.

4WDB-M1.2/1.8/1.2/2.9/24C4FJ6: electric grease lubrication pump; 4 grease outlets(pump elements); displacements of the 4 grease outlets are respectively 1.2ml/min, 1.8ml/min, 1.2ml/min, 2.9ml/min from left to right; the voltage is DC24V; installed with electronic programme control device; the oil tank volume is 4L; F type pump elements; the grease feeding port adopts Ø6 ferrule type straight thread connector.

2WDB-M1.8/3802CC: electric grease lubrication pump; 2 grease outlets(pump elements); the displacement of each outlet are all 1.8ml/min; the voltage is AC380V; no electronic programme control device; the oil tank volume is 2L; C type pump elements; the grease feeding port is a oil cup.

| Model | *WDB-M*/*C*** | |||

|---|---|---|---|---|

| Nominal displacement | ml/min | 1.2;1.8;2.9;4.2 | ||

| Nominal pressure | MPa | 25 | ||

| Pressure at safety relief valve | MPa | 25 | ||

| Number of grease outlet | PCS | 1~6 | ||

| Oil tank volume | L | 2 | 4 | 6 |

| Weight | kg | 6 | ||

| Electric motor power | W | 50 | ||

| Electronic programme control operating time | h.m.s | 0 ~99:59:59 | ||

| Electronic programme control stop time | h.m.s | 0 ~99:59:59 | ||